Electric Elevators (With Machine Room)

Gear Traction Lifts

Classic rope hoists have a gearbox attached to the electric motor that rotates the hoisting sheave and moves the rope. Geared traction elevators are powered by direct current (DC) or alternating current (AC) and have a maximum speed of 500 feet per minute. This speed limit is lower than gearless rope elevators but higher than many other types of elevators.

many people choose this system for its ability to travel a maximum distance of 250 ft. They also have fair installation and maintenance costs and low energy consumption. While their speed is slower than gearless elevators, geared elevators offer advantages in terms of energy efficiency as they use less power to rotate the pulley (pulley). In addition, these elevators have the ability to lift up to 13600 kg.

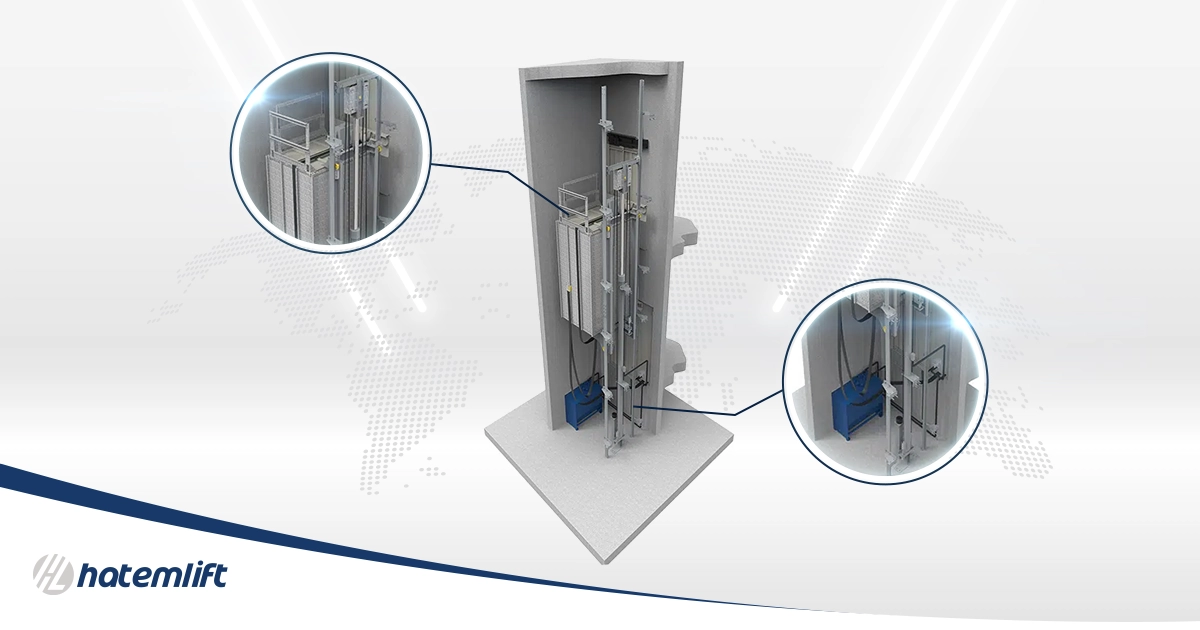

Machine Roomless Elevator, MRL Elevators, MRL Elevators, Gearless Traction Elevators

These traction elevators have the wheel directly connected to the electric motor. Gearless traction elevators have a very high travel speed, meaning they can go up to 2000 ft per minute and travel great distances. Its maximum travel distances are almost 2000 ft and therefore the best and only option for tall buildings. These elevators were capable of being used in any building at any height and had a much higher speed than other hydraulic elevators. The gearless traction system has since proven so durable that even today it is the best and most reliable option available for high-rise applications. These elevators operate using a wire cable (hoisting ropes) that attaches to the top of the elevator and wraps around the pulley at one end. The other end of the cable is attached by a counterweight that rises and falls in the lift path. The weight of the car and the counterweight together press the cable, which then turns the pulley and the elevator starts to move. To keep the load on the electric motor to a minimum, the counterweight is matched to the weight of the elevator car and half the load of the passengers. As the elevator car moves up, the counterweight starts to move down, thus balancing the elevator load. This significantly reduces energy consumption, as the engine only weighs half the cabin load. the counterweight matches the weight of the elevator car and half the load of the passengers. As the elevator car moves up, the counterweight starts to move down, thus balancing the elevator load. This significantly reduces energy consumption, as the engine only weighs half the cabin load. the counterweight matches the weight of the elevator car and half the load of the passengers. As the elevator car moves up, the counterweight starts to move down, thus balancing the elevator load. This significantly reduces energy consumption, as the engine only weighs half the cabin load.